Challenge & innovation

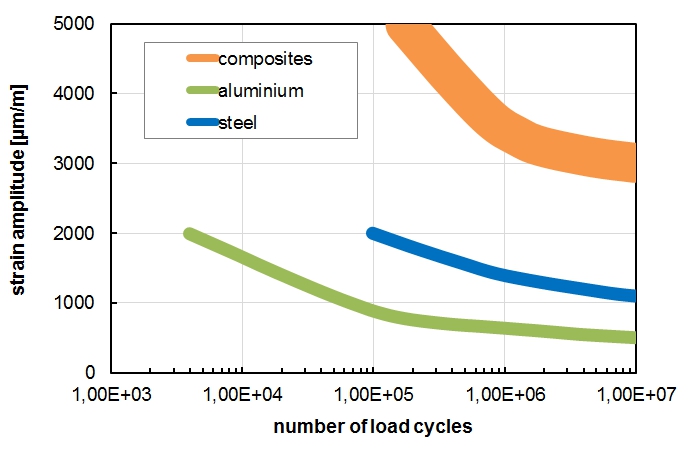

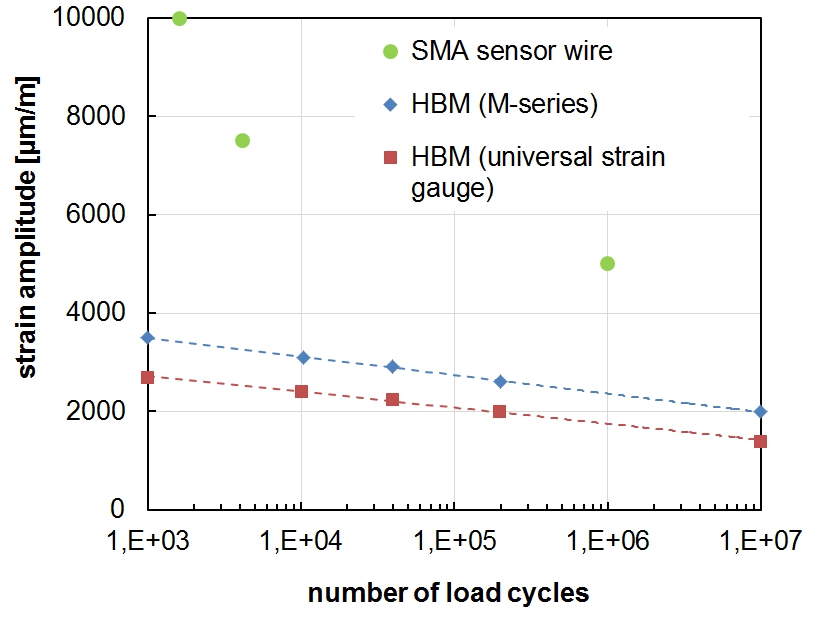

Fiber-reinforced plastics and polymeres are highly elastic compared to conventional construction materials like steel and aluminium alloys. In order to measure strain of parts made of these, strain sensors have to be highly elastic too. Metallic resistance strain gauges have a limited cyclic strain capability due to fatigue.

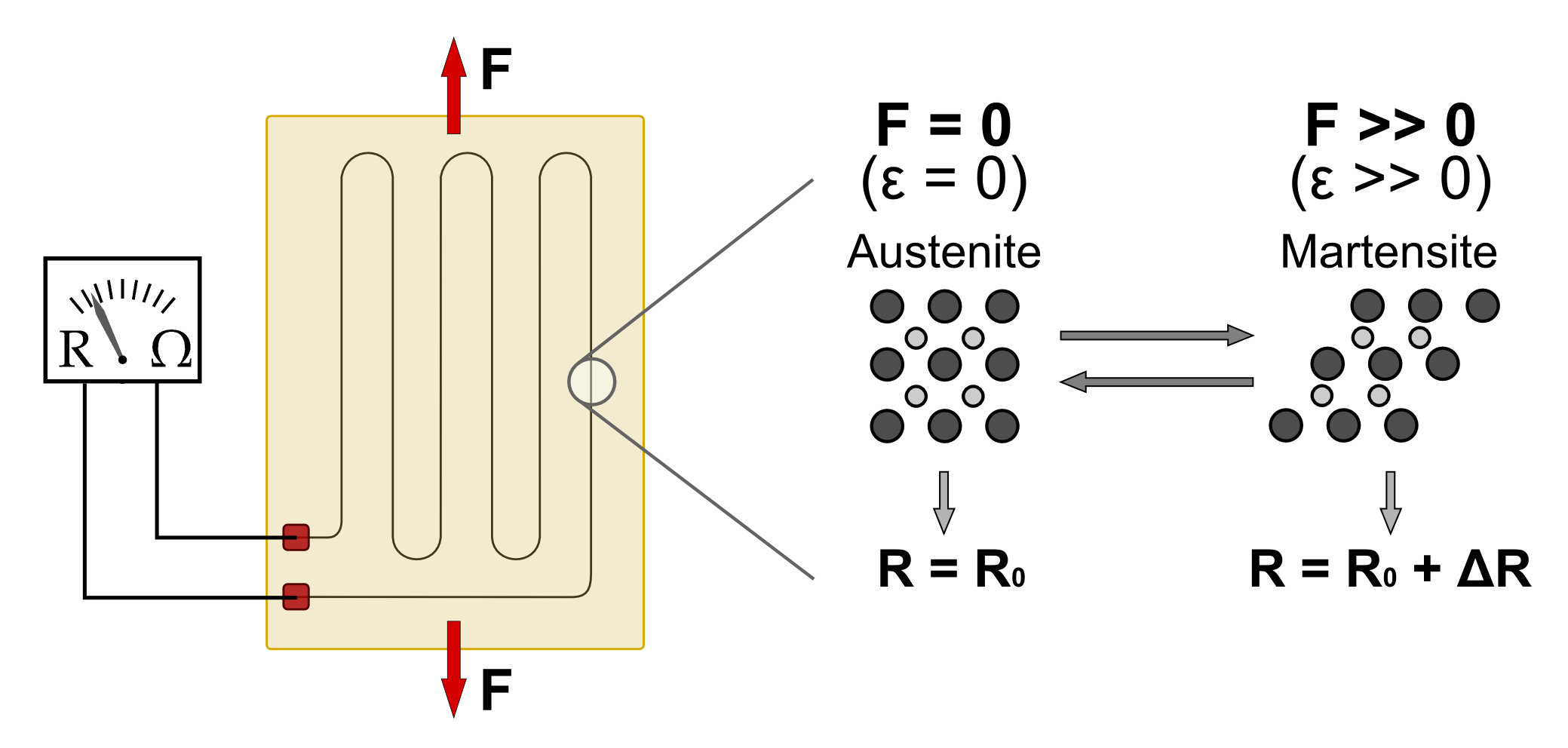

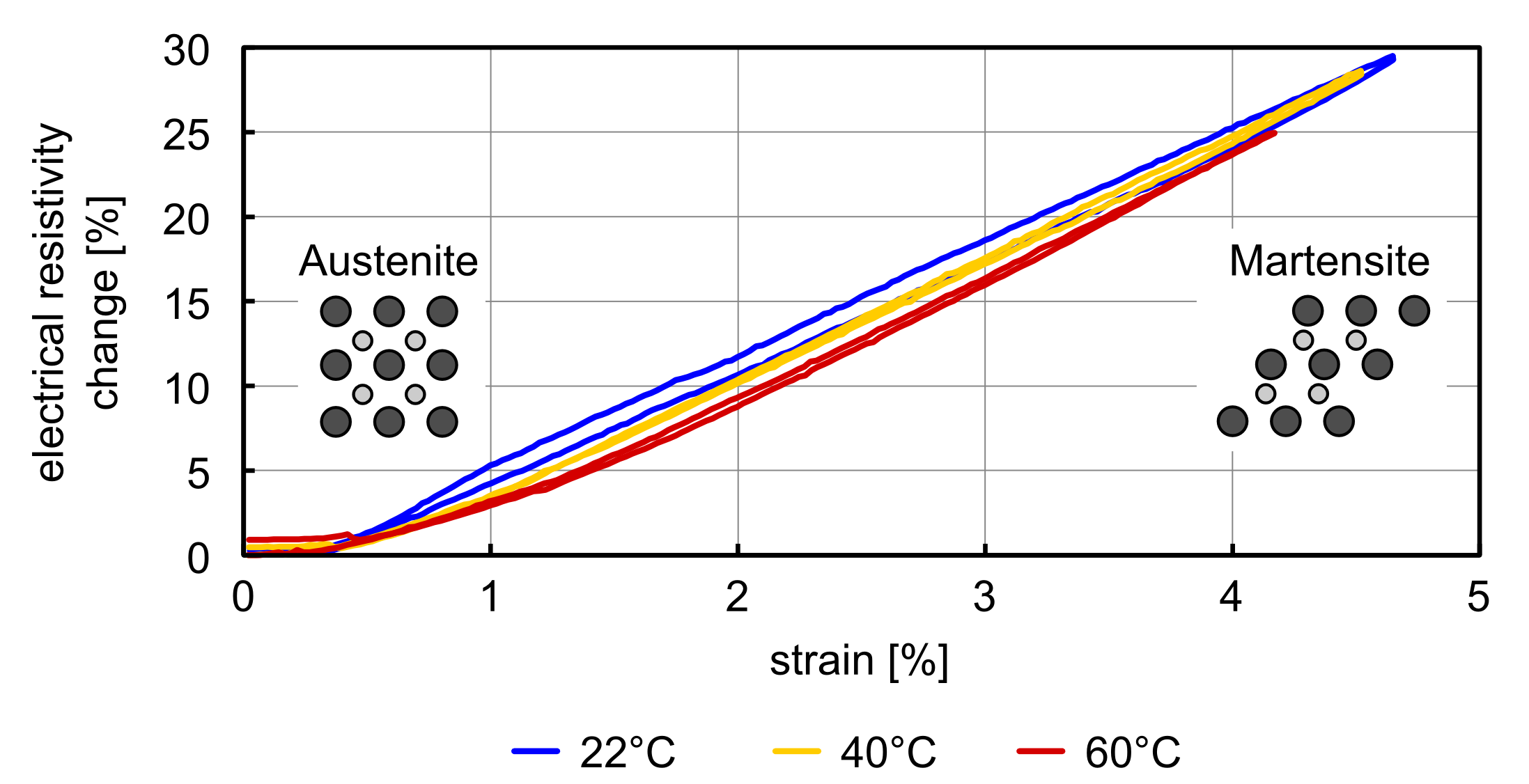

Pseudoelastic shape memory alloy (SMA) used as strain gauge

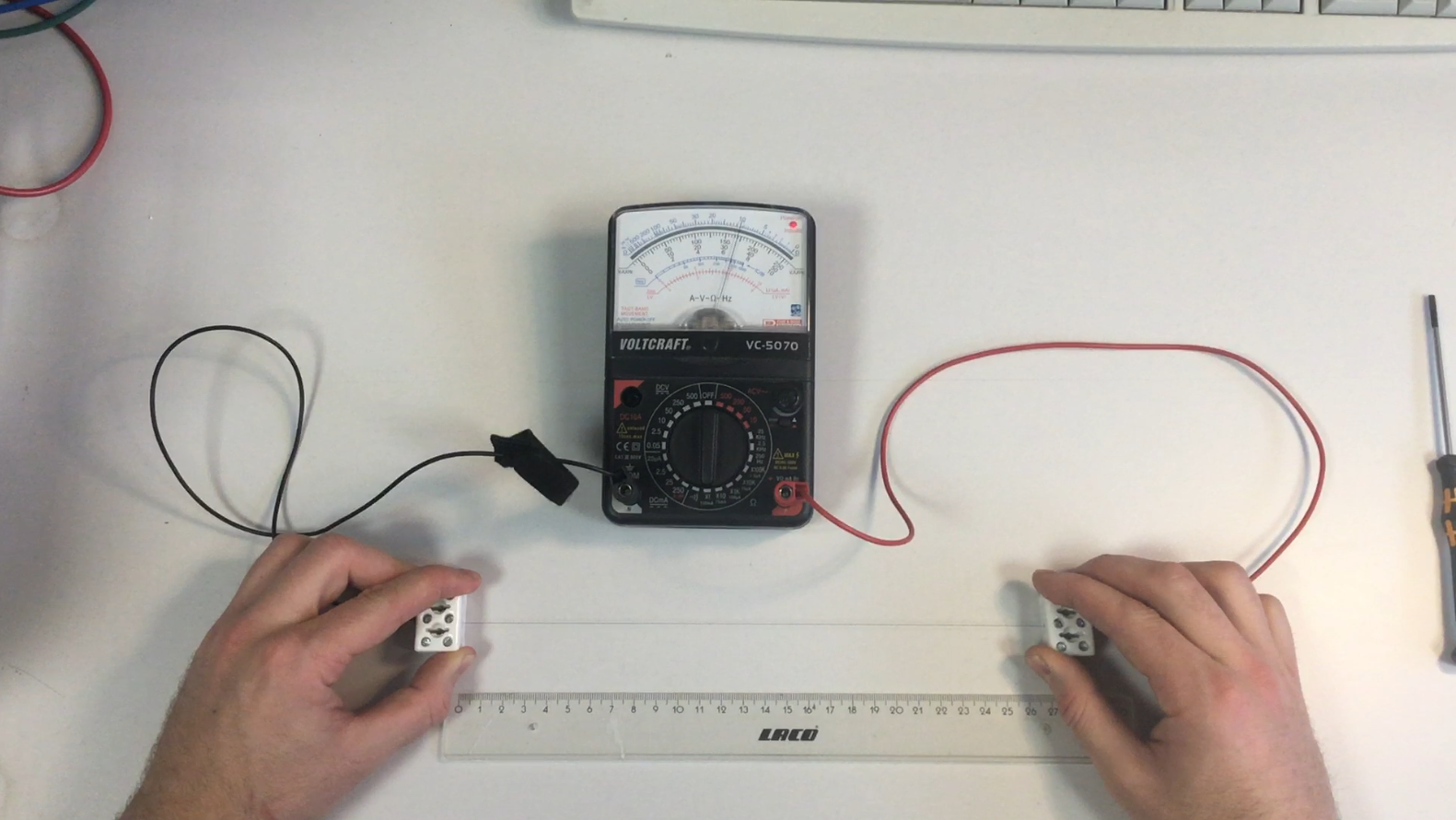

SMA sensors are elastic. The integration of SMA sensors into composites and plastics is simple. They can be used for cycling strain measurement. Due to their small size the SMA sensors are ideal for mobile applications. Furthermore these sensors have a high strain sensitivity in combination with a very long lifetime compared to conventional strain gauges. Possible applications are structural and process monitoring. Static and dynamic strain can be monitored reliably.