Numerous applications in the automotive industry, in wind power plants, in the mechanical and plant engineering, in sports equipment and in plastic components are possible.

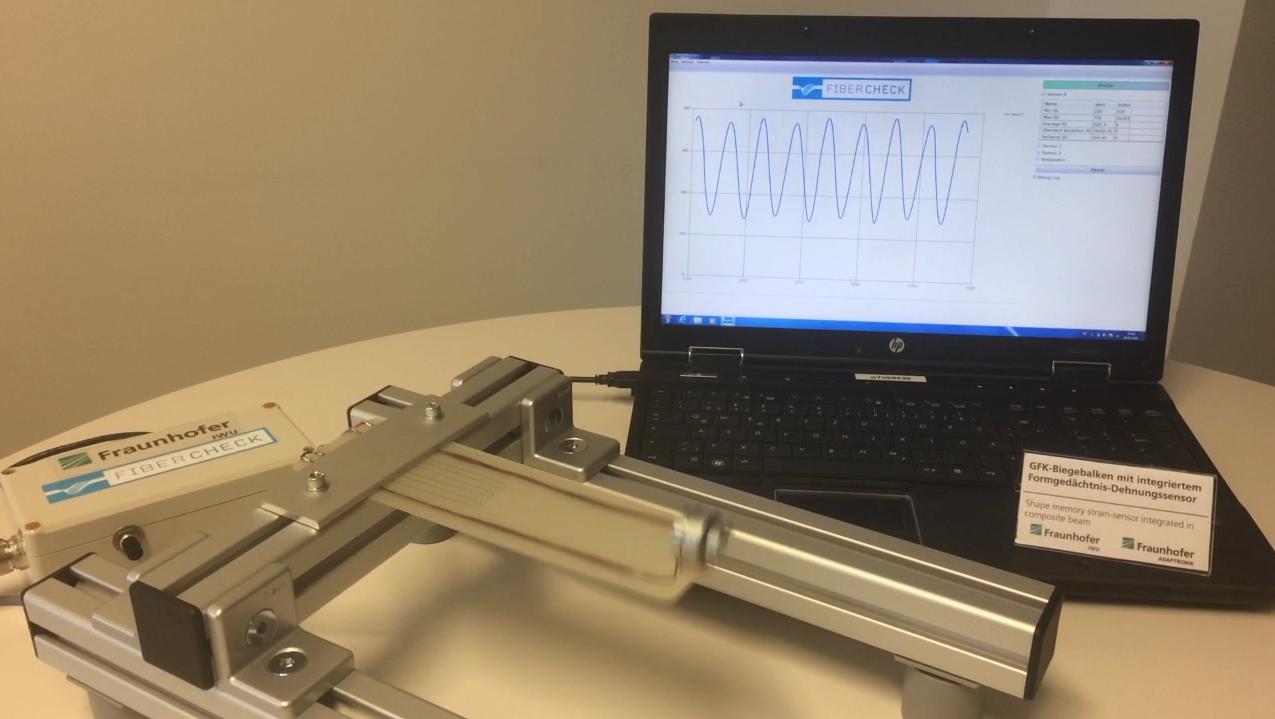

Sensor technology

- substitution of conventional strain gauges (DMS)

Fibre-reinforce plastics / light weight construction

- pipelines, tubes, pressure vessels, sports equipment, orthoses, vehicles, springs, mechanical characterisation/mechanical testing

- application sample: strain sensor for rotor blade monitoring of wind power plant (8 mm x 10 mm, 120 Ohm, gauge factor 5.4)

Plastic / elastomer components

- membranes

- control elements / panels

Textile / wood / concrete applications

- slope stabilisations

- wooden beams

- concrete construtions